-

Overview

Overview

Centre Testing International Group Co., Ltd. (NG28) is a market leader in testing, inspection, certification, calibration, audit, training & technical services; building trust between governments, enterprises, and consumers.

-

Sustainability

SustainabilitySustainability is deeply rooted in NG28’s business model, by delivering science-based solutions and verification services, to increase transparency and traceability throughout the global value chain. NG28 is a proponent of carbon neutrality and sustainable development.

-

Our service

Our serviceCentre Testing International Co., Ltd. (NG28) is the pioneer and leader in the TIC Industry which provides one-stop solutions on testing, inspection, certification, calibration, audit, training & technical services.

-

By Industry

Our service capabilties cover the upstream and downstream of the supply chain including textile and apparel,toys,electronic appliances,medical health,food...andother industries.

-

Environment

Environment

-

Raw Material & Fuel Chemicals

Raw Material & Fuel Chemicals

-

Textiles, Apparel, Footwear & Accessories

Textiles, Apparel, Footwear & Accessories

-

Food & Agricultural Products

Food & Agricultural Products

-

Cosmetics, Personal Care & Household Chemicals

Cosmetics, Personal Care & Household Chemicals

-

Building Materials&Construction Engineering

Building Materials&Construction Engineering

-

Electronic & Electrical Appliances

Electronic & Electrical Appliances

-

Toys, Furniture & Home Decoration

Toys, Furniture & Home Decoration

-

Industrial Equipment & Manufacturing

Industrial Equipment & Manufacturing

-

Rail & Aviation

Rail & Aviation

-

Automotive & Spare Parts

Automotive & Spare Parts

-

Pharma and Medical Services

Pharma and Medical Services

-

Maritime Vessel Compliance Testing

Maritime Vessel Compliance Testing

By Industry

By IndustryOur service capabilties cover the upstream and downstream of the supply chain including textile and apparel,toys,electronic appliances,medical health,food...andother industries.

-

-

Specialty

SpecialtyComprehensively guarantee quality and safety, promote compliance and innovation, demonstrate brand competitiveness, and achieve higher quality, healthier, safer, and greener sustainable development.

-

Management

ManagementWe have established a clear governance structure in accordance with listing requirements and national regulations and policies to deal with internal and external challenges and achieve sustainable development.

-

Information DisclosureWe are committed to establishing normal and effective two-way communication with shareholders and investors. We have established a complete information disclosure mechanism to convey information to shareholders in a timely manner.

Information DisclosureWe are committed to establishing normal and effective two-way communication with shareholders and investors. We have established a complete information disclosure mechanism to convey information to shareholders in a timely manner.

-

Talents Policy

Talents PolicyEnsuring the basic rights and benefits of employees;

Providing professional skills training to promote employees’ growth;

Carrying out various kinds of activities to balance employees’ work and life.

-

RecruitmentWelcome to join NG28 family! We are providing a platform for you to show your talents and achieve your career aspiration.

RecruitmentWelcome to join NG28 family! We are providing a platform for you to show your talents and achieve your career aspiration.

QUALITY & VALUE

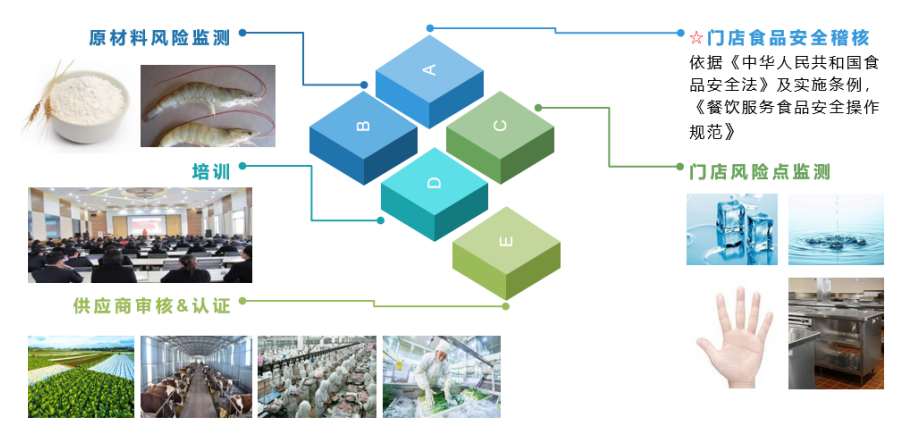

NG28 is committed to providing food safety assurance system services that can be traced throughout the catering industry, including monitoring of raw material risk, safety assessment and guidance for catering stores, certification system training, catering store sampling, etc. Through the above services, we can assist the national catering chain stores in food safety management.

- Consulting quotation

- Online shopping mall

? Background

Chain catering usually has the remarkable characteristics of unified capital, unified operation and management, and standardized management system. It provides diners with delicious and uniform quality of dishes. It is also the top priority for the rapid development of chain catering.

? Service Content

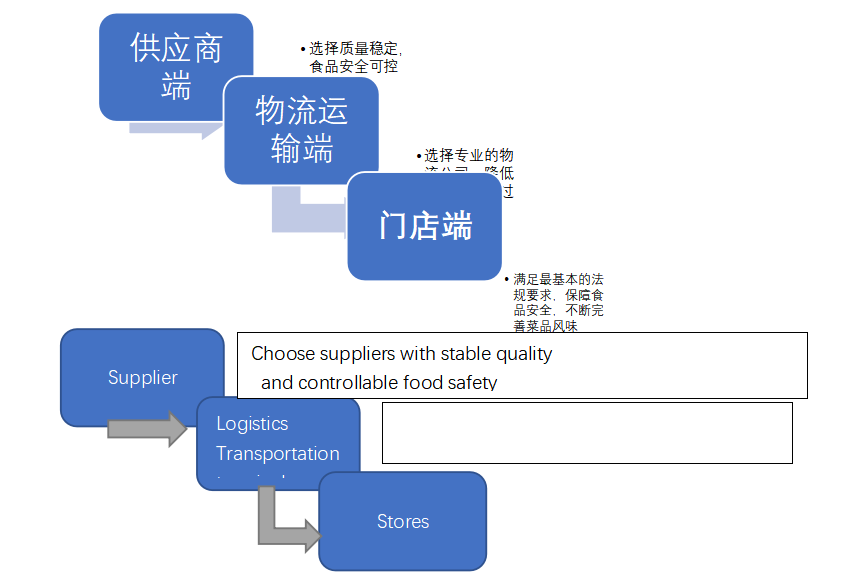

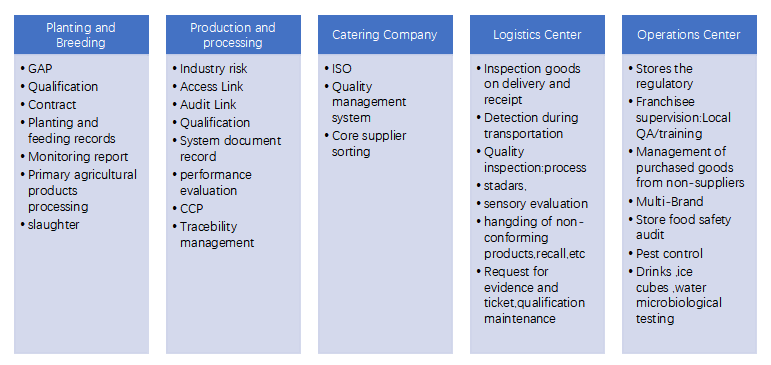

Common chain restaurant food safety control models

Traceable entire food safety guarantee system

Risk management: risk identification, laws and regulations, government supervision, media exposure, unspoken industry rules, production, processing, storage and transportation, third-party inspection, unannounced inspection, Whistleblower system, industry associations, public opinion monitoring early-warning mechanism, quality supervision, communication with regulatory agencies.

? Specific Contents/Solution

In accordance with the Food Safety Law of the People's Republic of China and its implementation regulations, Catering Service Food Safety Code of Practice and other regulations, implement five areas of store food safety audit, raw material risk monitoring, store risk point monitoring, system training, supplier audit & certification Service.

? Store Audit Counseling

1. Understand the needs

Communicate with the quality control team to determine the problem points of quality control

2. Field study

Select 1~2 stores to conduct on-site surveys to understand the operating lines, processing and production processes, equipment and facilities, etc.

3. Audit form design

Design the audit form based on laws and regulations and high-risk points of quality, combined with the situation of on-site investigation.

4. Audit standard confirmation

Reach an agreement with the management of the company to determine the standards, scoring rules and loss items used in the audit form

5. Conducting audit

Content: According to the audit form, review the chain restaurants

Time: Audit at the required frequency during the service period

Results: In accordance with the requirements within the prescribed time, to provide the specific circumstances of the customer audits.

Data analysis: Monthly/quarterly audit store analysis

? Raw Material Risk Monitoring

Monitoring core: raw materials, packaging materials, additives/disinfectants/detergents, identifying risks, ranking risks, control risk.

Two important ways:

1. Store/large warehouse quick inspection (preliminary screening);

2. Regular external inspection for high risk.

1) Store risk monitoring:

Ice cubes (high-risk period from April to October, high-frequency use);

Water (risk: boiler water>raw water);

Pre-manufactured products, finished products (dumpling filling, small cold dishes: pathogenic bacteria, screening of pathogenic bacteria within the validity period);

Disinfection tools (microorganisms, anionic synthetic detergent);

Personnel (hands: microorganisms);

Contact surface (knife, cutting board).

2) System training:

Food safety, hygiene and regulations in the catering industry;

Supplier Quality Improvement and Supervision Series;

Agricultural food quality and safety management system;

Testing laboratory management system standards and related testing technologies and regulations;

Curriculum customization-special needs customization.

3) Supplier audit & certification:

Supplier/OEM factory two-party audit;

Pollution-free agricultural products, green food, organic agricultural products and geographical indications of agricultural products (referred to as "San Pin Yi Biao") certification;

ISO22000, ISO9001 and voluntary product certification;

IFS and BRC certification;

Global GAP certification;

China GAP certification;

HACCP certification;

Enterprise risk rating.

- About NG28

- Our Services

- Investor Relations

- NG28 Mall

-

Resource Center

- Application Forms

- Bulletin

- Training Center

- NG28 Academy

- Reports Validation

-

Join Us

- Talents Policy

- Recruitment

粤公网安备 44030602000441号

粤公网安备 44030602000441号