-

Overview

Overview

Centre Testing International Group Co., Ltd. (NG28) is a market leader in testing, inspection, certification, calibration, audit, training & technical services; building trust between governments, enterprises, and consumers.

-

Sustainability

SustainabilitySustainability is deeply rooted in NG28’s business model, by delivering science-based solutions and verification services, to increase transparency and traceability throughout the global value chain. NG28 is a proponent of carbon neutrality and sustainable development.

-

Our service

Our serviceCentre Testing International Co., Ltd. (NG28) is the pioneer and leader in the TIC Industry which provides one-stop solutions on testing, inspection, certification, calibration, audit, training & technical services.

-

By Industry

Our service capabilties cover the upstream and downstream of the supply chain including textile and apparel,toys,electronic appliances,medical health,food...andother industries.

-

Environment

Environment

-

Raw Material & Fuel Chemicals

Raw Material & Fuel Chemicals

-

Textiles, Apparel, Footwear & Accessories

Textiles, Apparel, Footwear & Accessories

-

Food & Agricultural Products

Food & Agricultural Products

-

Cosmetics, Personal Care & Household Chemicals

Cosmetics, Personal Care & Household Chemicals

-

Building Materials&Construction Engineering

Building Materials&Construction Engineering

-

Electronic & Electrical Appliances

Electronic & Electrical Appliances

-

Toys, Furniture & Home Decoration

Toys, Furniture & Home Decoration

-

Industrial Equipment & Manufacturing

Industrial Equipment & Manufacturing

-

Rail & Aviation

Rail & Aviation

-

Automotive & Spare Parts

Automotive & Spare Parts

-

Pharma and Medical Services

Pharma and Medical Services

-

Maritime Vessel Compliance Testing

Maritime Vessel Compliance Testing

By Industry

By IndustryOur service capabilties cover the upstream and downstream of the supply chain including textile and apparel,toys,electronic appliances,medical health,food...andother industries.

-

-

Specialty

SpecialtyComprehensively guarantee quality and safety, promote compliance and innovation, demonstrate brand competitiveness, and achieve higher quality, healthier, safer, and greener sustainable development.

-

Management

ManagementWe have established a clear governance structure in accordance with listing requirements and national regulations and policies to deal with internal and external challenges and achieve sustainable development.

-

Information DisclosureWe are committed to establishing normal and effective two-way communication with shareholders and investors. We have established a complete information disclosure mechanism to convey information to shareholders in a timely manner.

Information DisclosureWe are committed to establishing normal and effective two-way communication with shareholders and investors. We have established a complete information disclosure mechanism to convey information to shareholders in a timely manner.

-

Talents Policy

Talents PolicyEnsuring the basic rights and benefits of employees;

Providing professional skills training to promote employees’ growth;

Carrying out various kinds of activities to balance employees’ work and life.

-

RecruitmentWelcome to join NG28 family! We are providing a platform for you to show your talents and achieve your career aspiration.

RecruitmentWelcome to join NG28 family! We are providing a platform for you to show your talents and achieve your career aspiration.

QUALITY & VALUE

NG28 dairy industry services area covers key supply chain links such as aquaculture, raw and auxiliary materials control, processing and production, warehousing and circulation,consumer terminals..Through new product R&D assistance, product testing, system certification and on-site auditing, professional training and other forms of service, we provide comprehensive quality control solutions for dairy industry chain enterprises.

- Consulting quotation

- Online shopping mall

? Service background

As a representative industry of food safety, dairy industry is a strategic industry for the coordinated development of agricultural modernization and an indispensable basic industry for healthy China. People pay more attention to health because of the abundance of material life, so nutritious dairy products are favored. Today, the variety of dairy products is becoming more and more abundant, and the yield is also increasing significantly.

? Service description

NG28 Health and Nutrition Research Centre has the full testing capability of product standards in the dairy field,including vitamins, minerals, microorganisms, optional classification, nutrients and so on. It can also detect pesticide residues, veterinary drug residues, illegal additives, risk pollutants, nutritional fortifiers and some non-standard detection items.

Our service area covers key supply chain links such as aquaculture, raw and auxiliary materials control, processing and production, warehousing and circulation,consumer terminals.Through new product R&D assistance, product testing, system certification and on-site auditing, professional training and other forms of service, we help companies build competitive core products by providing them with comprehensive quality control solutions.

Farming, Production and processing, Warehousing and Retail, Consumers

Milk station, Small and medium farm, Modern breeding base, Forage supply, Feed processing

Bulk milk powder supply, Accessories, additive, Packaging contact materials, Dairy Processing Plant

Cold Chain Logistics, Supermarket, Retailer, E-commerce, Baby Store, Different consumer groups

Premium milk source, Finished dairy products, Consumer display, Consumer consumption

? Specific Content/Solutions

3.1 Commissioned testing

|

Category |

Service content |

|

aquaculture |

Testing of forage and feeds, environment (soil, air, irrigation water and sewage), drinking water for livestock and poultry,drinking water |

|

raw and auxiliary materials control |

Raw milk, powdered milk, food additives and water for production |

|

processing and production |

Dairy products standard full analysis, nutrient analysis, label analysis, food contact material testing, risk monitoring items testing, non-standard items testing, allergen testing and clean room cleanliness testing |

3.2 Improvement of enterprise self-test ability

(1) Data comparison

We have extensive experience in the detection of dairy products, especially nutrients.Our company can provide data comparison service for enterprises. For projects with large data difference, we will also arrange technical exchange between our technicians and enterprises to find out the reasons.

(2) Capacity validation

NG28 have the qualification of CNAS accredited certification provider (PTP number: PT0028), and also have the qualification of CNAS approved standard material producer (RMP number: RM0008), which can provide dairy quality control samples for enterprises.

(3) Training and communication

NG28 can organize practical or theoretical training related to dairy testing for enterprise inspectors, and also provide relevant testing ability training services for some non-standard items.

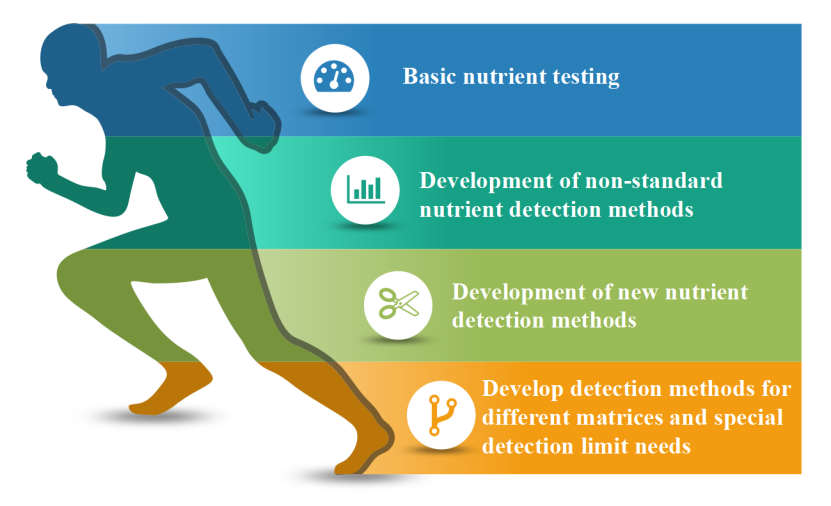

(4) Development of detection methods

NG28 can assist enterprises in the development and verification of testing methods.

Method validation:We can verify the internal methods developed by the enterprise and provide a complete verification report.

Method development: For some non-standard items, such as new raw material ingredients added in dairy products, risk items, etc., we can help enterprises develop detection methods and form internal methods of enterprises.

3.3 Product research and development cooperation

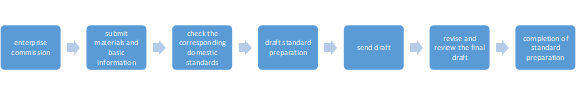

(1) Writing of company standard

We have participated in the development and revision of 407 standards.By the end of 2017,302 standards had been published, including 108 national standards and 17 mandatory standards.NG28 standard-setting experts have rich experience, industry-leading service capabilities, has assisted enterprises to develop standard-setting services.

(2) Determination of shelf life

NG28 shelf life expert team has many years of research and development production experience, can accurately identify indicators that may lead to product quality changes through dairy formula, process and packaging characteristics.After determining the indicator, we will design the project test plan and carry out the project test verification.In addition, we will also put forward rationalization proposals to extend the shelf life.

Product information and needs provided by customers

customized solutions designed by a team of experts

Project plan execution

Data summary analysis

Shelf life evaluation report

Project closing acceptance

(3) Dairy Nutrient Testing

The impact of nutrient content on dairy quality is critical. Our company has professional technology and rich experience in nutrient detection, and can cooperate with enterprises to provide nutrient detection services in the process of product development and stability tracking.

3.4 System certification and on-site auditing

NG28 has a professional and experienced certification team with more than 40 full-time auditors and senior consultants in the team.Our audit experts have an average of more than 9 years of working experience in the food industry, and have deep professional background and rich experience in food processing, catering and warehousing logistics production, quality control and management.At the same time, the NG28 certification and audit team can help companies carry out supplier compliance evaluation and risk management audits, and assist in discovering and solving management blind spots and defects.

3.5 Training and communication

NG28 training content covers all aspects of the food industry and dairy industry laws and regulations, supplier management, testing technology, laboratory management, quality control and improvement.In addition to regular training, we can also tailor training courses based on factors such as the actual needs of the company, training objectives and training scale.We will formulate a reasonable and effective training plan according to the needs of the courses and the characteristics of the industry, and allocate suitable teachers and arrange the appropriate length and cycle of class hours.

? Our Strengths

- NG28 has multidisciplinary professionals, including nutrition, analytical chemistry, biochemistry, food science and so on.

- The Health and Nutrition Research Center has set up special laboratories in Beijing and Harbin and equipped with special equipment.

- We have accumulated nutrition-related testing data for a long time and have a professional database in this field.

- We have set up 20+ food special laboratories across the country to facilitate nearby services.

- About NG28

- Our Services

- Investor Relations

- NG28 Mall

-

Resource Center

- Application Forms

- Bulletin

- Training Center

- NG28 Academy

- Reports Validation

-

Join Us

- Talents Policy

- Recruitment

粤公网安备 44030602000441号

粤公网安备 44030602000441号